Reconditioning

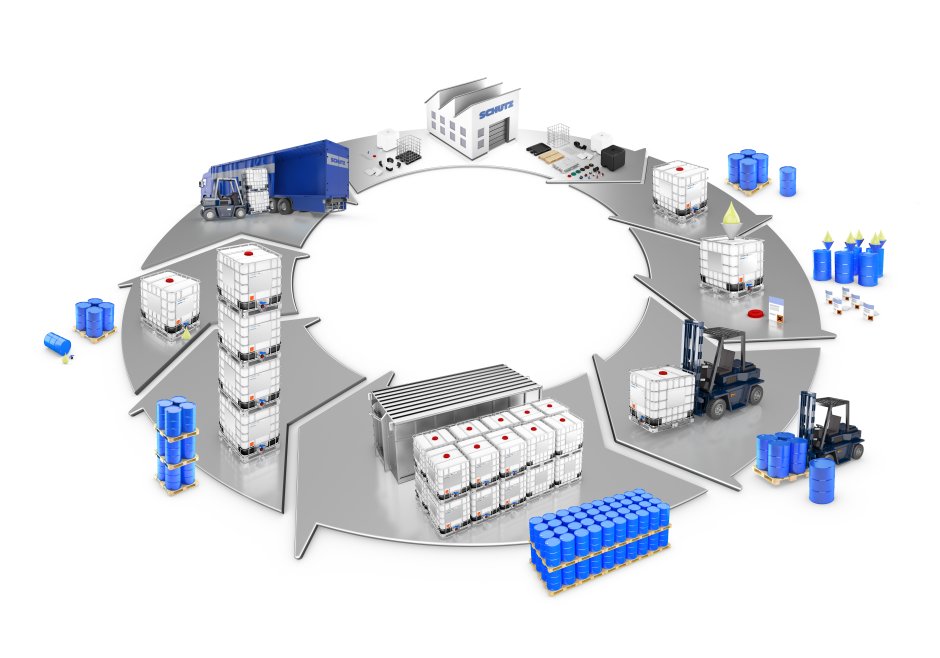

IBCs retrieved by SCHÜTZ are not only washed and cleaned. All components that come into contact with the filling goods are exchanged and replaced with new components. All models receive a new permit and offer complete product safety.Delivery/Transport

SCHÜTZ IBCs save on space: With each transport, with each loading process – in comparison with a steel or plastic drum – 25% more filling goods can be transported with the same space requirement.Filling:

With 1,000 litres of filling goods, 5 drums all need to be opened, filled, closed and, if applicable, labelled. With an IBC, all of these steps need only be carried out once.Handling

Drums must be individually or jointly stretched on pallets; IBCs include a pre-selected pallet and can be transported directly as a fixed unit. Accordingly, it will take 2 workers 90 minutes to load and unload a truck with (unstretched) drums, while a truck with IBCs can be unloaded using a forklift truck in only 20 minutes.Transport

Thanks to standardised ISO dimensions, IBCs ideally utilise the entire volume of the container. In comparison: a 20’ container can only hold 80 drums with 16,000 litres, while 20,000 litres of your product can be transported in 20 IBCs in the same space.Storage

SCHÜTZ IBCs save space because an IBC holds 25% more filling goods in the same amount of space as a steel or PE drum.Emptying

Emptying the IBC is easy thanks to the standard discharge valve or specialised emptying systems. This process is much easier and faster than emptying drums, as 5 drums need to be individually opened, checked and emptied for the same volume of filling goods.Collection

SCHÜTZ IBCs are collected from the consumer after emptying by the worldwide SCHÜTZ TICKET SERVICE.