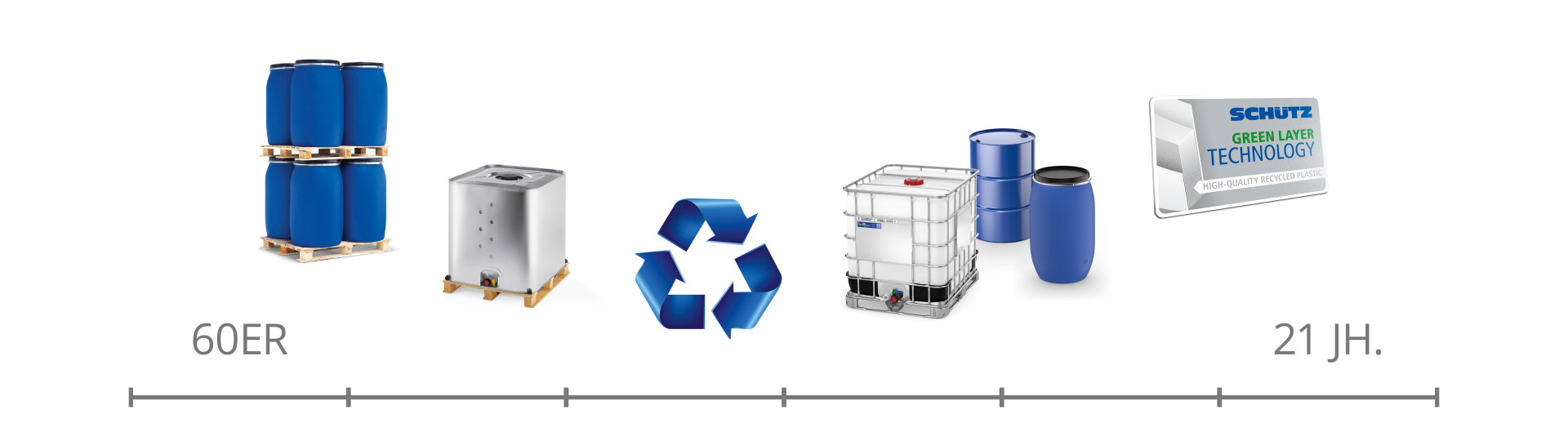

Depending on the area of application, packaging performs different functions. Essentially, packaging ensures the efficient distribution of goods. A range of different types of packaging is used to transport goods of different classes from the point of origin to the consumer. Industrial and bulk hazardous goods packaging in particular protects the environment from exposure to hazardous products and, thanks to the stable construction, also protects the goods that are being transported.

Sustainable packaging

in the industry

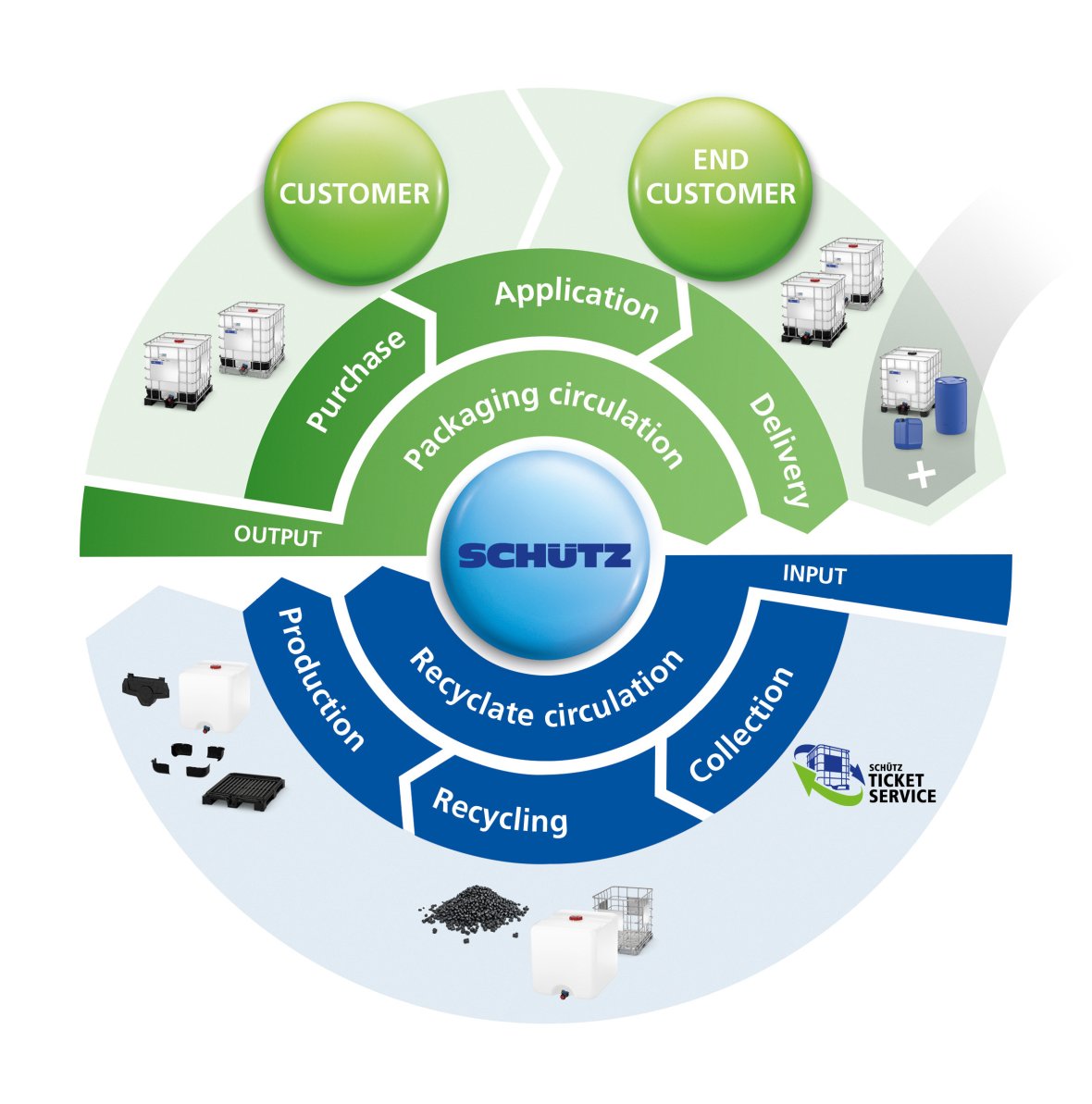

Companies today are expected to reduce their carbon footprints. One of the easiest and fastest ways of achieving this goal is the consistent use of sustainable industrial packaging. Sustainable packaging is a central factor in any green supply chain. This page provides information about the choice of industrial packaging that is available, details of the European Union’s framework conditions for packaging manufacturers, and how companies can establish and maintain an eco-friendly packaging cycle.