Legal provisions

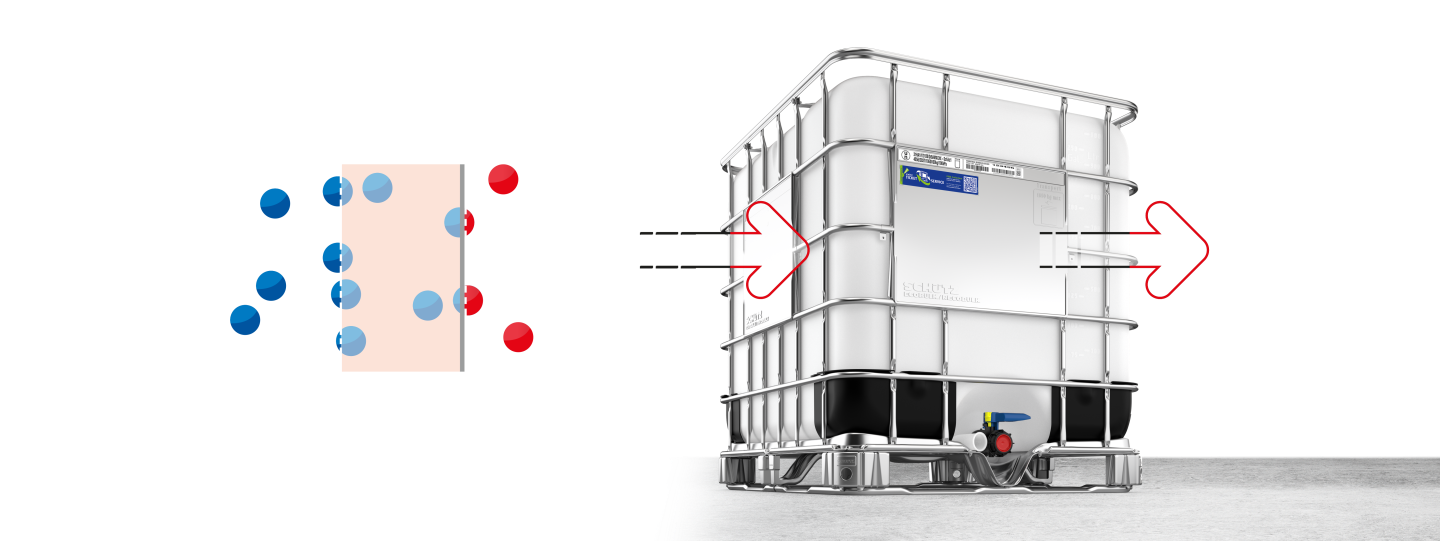

Due to the potential effect of permeation during the transport of hazardous goods, legislators have defined very precise regulations for the containers that may be used.

Chapter 4.1.1.2 of the existing Transport Act (see the international IMDG Code and regional rules and standards, such as ADR) stipulates:

Those parts of the packaging, including bulk packaging (IBC) and large packaging units, which come into immediate contact with dangerous goods:

(c) must prevent the permeation of dangerous goods which could present a hazard under normal transport conditions.

If necessary these containers must be equipped with a suitable inner layer or treatment.